16th – 27th July 2012

In addition to our departmental overhaul and supply work we have had a number of events and changes taking place such as a company bike ride, BBQ, bowling and office redesign.

Cycling

Some of the EGS team (Wayne, April, Michelle, Sarah, Mick, Chris, James and Andy) completed a 25 mile bike ride around Colchester to raise money for St Helena Hospice and the PH Association. Despite the miserable weather; amber weather warning for rain, flooding and risk of storm, the team pulled through and made a fun day of the challenge.

We all stuck together as team, letting no man fall behind, and celebrated with a lunch at the end. Next time we’re planning to step up the mileage and complete a 50 mile course. Check out photos of the team which can be found to the right.

Olympic BBQ and Bowling

To celebrate the launch of the Olympics, this Friday (27th) we will be seeking to tie up the day’s activities for 13.30 and holding a BBQ on site with good food, drink and music. BBQ expert Wayne will be manning the BBQ, and some of the team will then be heading off for a night of bowling.

Office Overhaul

You may have seen on our Facebook, Twitter or Google Plus pages that the EGS offices have undergone some serious work.

The senior management office has been restructured and redecorated. A separate office for accounts and quality control has been built for Holly and Marie. Finally the administration offices have been redesigned to a larger open plan office. This redesign work was part of a larger strategy to improve efficiency and communication. You will see to the right a picture of the last office to be overhauled in which the Overhaul and Spares departments can work more effectively in their appropriate teams.

Mechanical Overhaul

Whilst many changes and events have taken place, we haven’t let it affect our work, of course! Here are a few of the projects we have been working on:

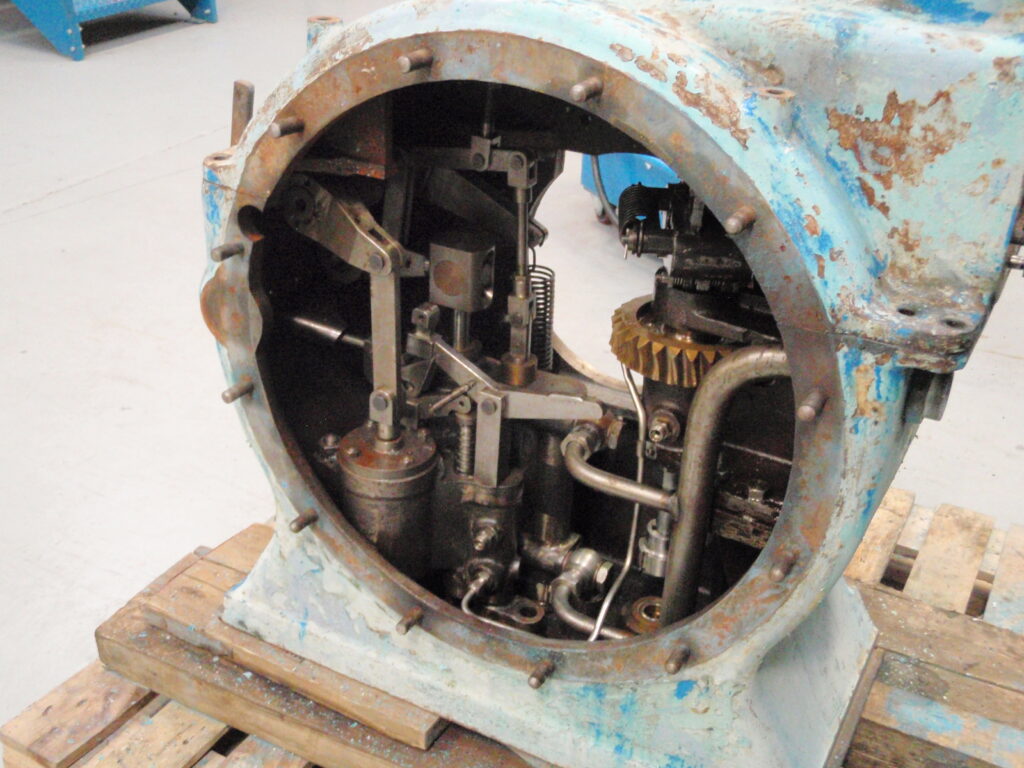

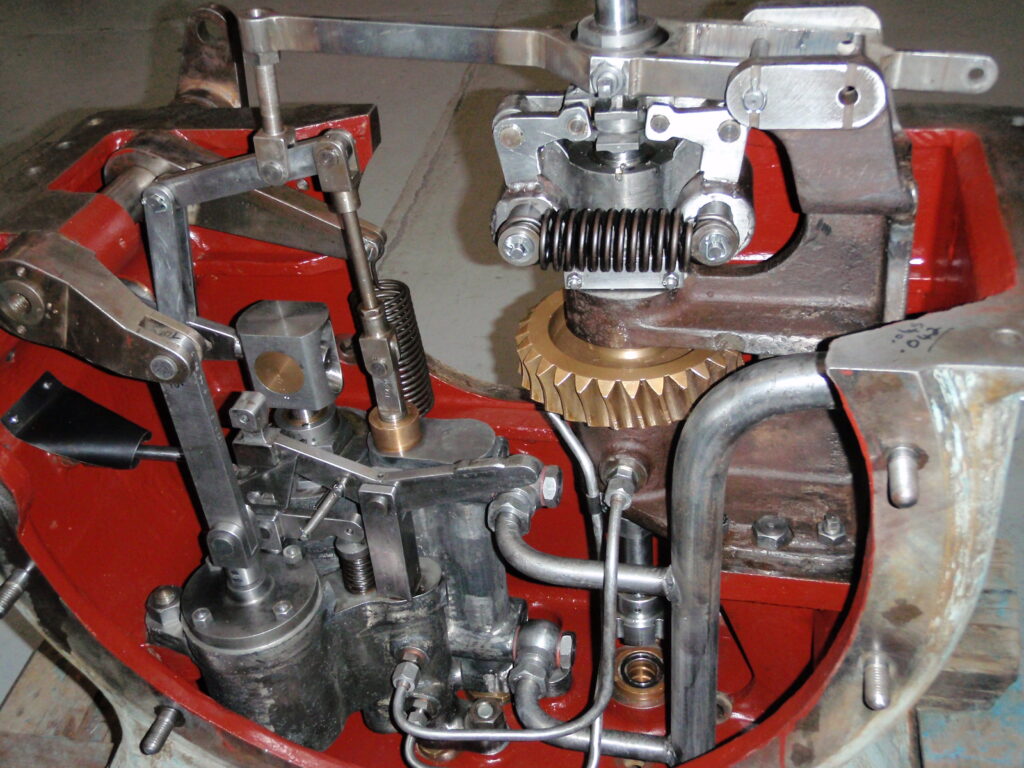

Technician James is working on two Woodward UG8D exchange build governors. Pictures of components laid out can be found to the right.

GT power oil solenoid block

Service Manager Steve has been working on the overhaul of a GT power oil solenoid block for a power generation customer who has been experiencing some issues of the valves sticking.

Steve went about this project firstly by carefully sketching the solenoid assembly, taking notes and photographs. He stripped and cleaned all elements and then individually rebuilt each of the four valves.

He then preceded to the test the individual valves consisting of three solenoid valves and one double solenoid. The three individual solenoids form a two out of three voting trip system, of which Steve tested all possible combinations. He then tested the final valve, a double solenoid acting as an on/off trip in addition to testing the reassembled complete unit, which seemed to be operating perfectly to specification with no issues of sticking.

The customer will come to site Friday 27th to witness these tests which will be performed again by Steve. All results will be explained to the customer who will check all is satisfactory in addition to having resolved the issue of sticking.