The Steam turbine combined trip and throttle valve was received in a very poor condition and appeared to have not been used for some considerable time.

Trip and throttle valves are integral to the safety and precisely control the speed / load of the steam turbine, typically drive an alternator, pump or fan.

Steam valves generally get very rusty, due to the nature of the harsh environment, as you can see from the before photograph.

Sequence of overhaul;

The first step we take when performing an overhaul on any valve is to photograph its initial state and also as we gradually strip the valve, more photos are taken.

The valve is then dismantled and cleaned by paint stripping and bead blasting to remove all rust and dirt, then chemically cleaned.

Once all parts are clean, they are then laid out and inspected for wear, damage and corrosion. Only then our technicians will ascertain what will need replacing.

A Standard overhaul kit was fitted, in addition to valve stems, pins, main studs, washers, adjusting screws, main gaskets used plus machining on some major parts carried out.

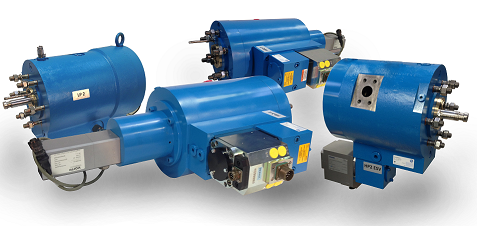

The valve was then meticulously re-built and mechanically tested to ensure the unit was back to original specification.

The finished valve was dispatched in a bespoke wooden packing case and delivered safely back to the customer by our own EGS transport.

For a enquiries, please contact wayneward@egsgov.com