Friday 20th April 2012

Following the soft launch of the website on Tuesday the 10th of April, the new site is officially launched today.

As you can see we have rebranded to EGS (from Essex Governor Services) and have today launched a significantly revamped edition of the old website; a key part of our new approach to the web.

Strategy

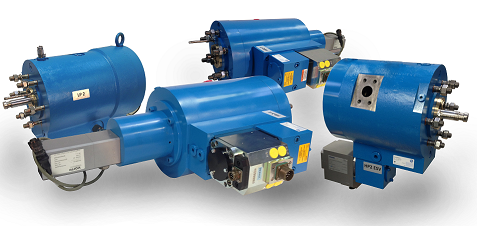

Over the years, we have grown our reputation for high quality products and a precise, expert service which is second to none. The company has steadily expanded into new sectors from rail and marine, to petrochemical, utilities and industrial whilst developing the service offering to cover not only mechanical overhaul, but overhaul of electronic governors and turbine controls as well as actuators, steam valves and upgrades to control systems. As a result, EGS have been minimising risk, maximising profitability and equipping customers to make the most of the resources they have to hand. We wanted to showcase this growth and development to our customers and demonstrate that whilst remaining dedicated to the root of the business, we now offer the latest technologies.

When going about our web strategy, we didn’t simply want to display basic information about the company, we instead wanted to take the ‘user-centred’ approach and set out to discover what existing customers wanted to see. After conducting some research alongside our customers on their expectations and hopes for the website (we very much appreciate all those customers that took the time to assist us on this) we combined this valuable insight with the expertise of Cyber-Duck to identify which areas would require the greatest emphasis once the website reached wireframing and ultimately design.

The end result – The new brand

When considering the project, we decided that our renewed approach to the web and showcasing of the new areas of our business would not be complete unless we also redesigned our brand to complement these changes. April worked alongside Cyber-Duck’s Senior Designer Raj on the design of the logo.

We found our old logo (all of which can be found within our history page) whilst conveying the global element to the business, it did not convey what we did as a company, and in general was quite unclear. The new logo, a more contemporary design, maintains the global image of our company whilst representing the present and future EGS; the controls side of our business. What’s more, as a logo it is unique and bold and hence very much conveys what we are about at EGS.

The end result – The new site

An important element to the resulting website is that it caters for both those customers that want to take the time to learn more about EGS product and service offerings, as well as those who simply want fast, straight-forward access to the particular service, product or contact they are looking for.

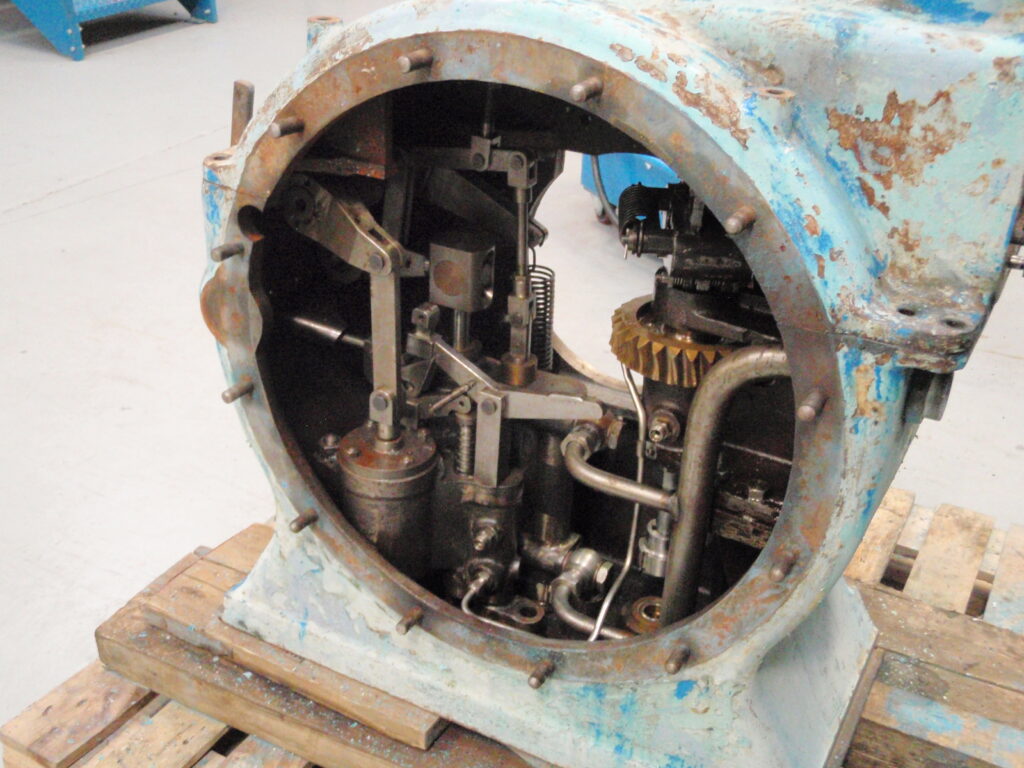

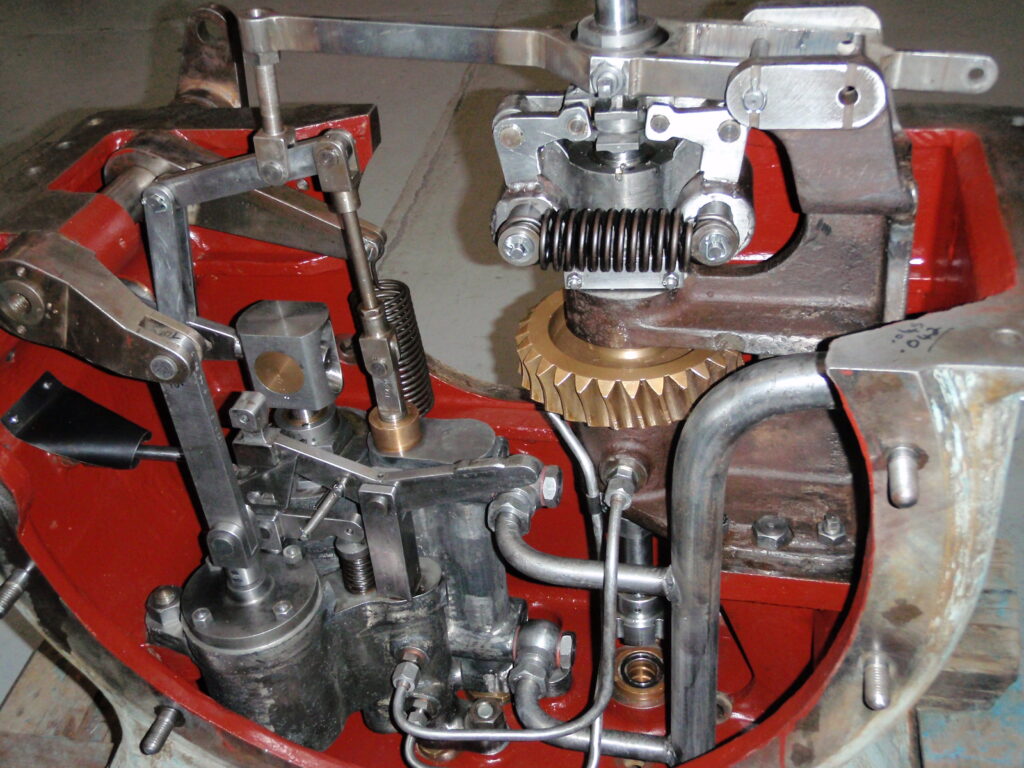

We have informative videos of employees as well as intriguing content on how a governor is stripped down, inspected and restored to as-new condition. In addition, there is extensive information on all the products we supply and maintain as well as some examples of projects the company has worked on and the services we offer. We have included a history page to document the development of the company to date, and a team page to showcase our marvellous team demonstrating their skill and expertise, enabling our customers to have every confidence in the staff working with their product.

Moving forward

During the redesign process it was important that we got the point across just how focussed we are on our customer relationships, whilst also ensuring our newer product and service offerings are conveyed well. Now we have our website up and running, we will keep you up to date on our various day-to-day activities, in addition to exciting and unique projects that we take on as they happen. We are also keen to push our social media campaign, having set up Facebook, Twitter, Google Plus and Linked-In pages in addition to continuing to add to our website and researching what our customers would like to see.

We are currently working on producing an interactive diagram that, aside from the video demonstrating how a typical mechanical governor is assembled, will show how the governor works from the inside.

Throughout the redesign process, we have been looking at ways to improve our service, product offering, and the way our company operates. We are currently undergoing a significant refurbishment project within our offices with the view of improving efficiency and communication. We take each project step by step, but never cease to look to improve our business, move forward and ensure the customer is at the centre of each measure.